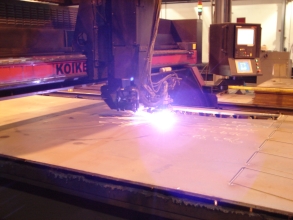

Plasma cutting technology can cut to higher tolerances than flame cutting as well as cut straight or beveled edges to your specifications. Water tables reduce temperature deformation and CNC programs ensure optimum nesting to reduce scrap.

The plasma cutting process uses an electrical arc to turn inert gas into a plasma arc hot enough to melt carbon steel plate and make a clean, precise cut. The cutting head is programmed to cut complex shapes and bevels to exacting tolerances.